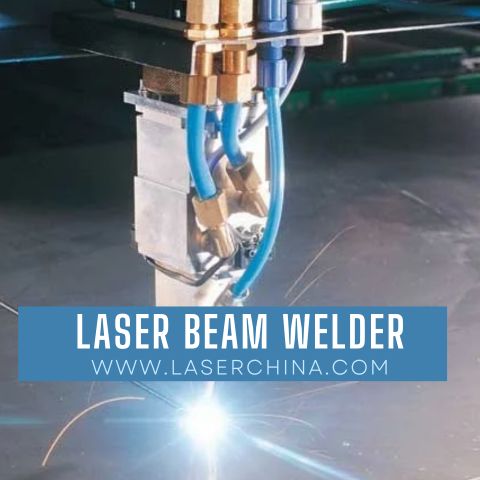

In the fast-evolving world of manufacturing and fabrication, advanced tools are shaping how industries operate. One standout technology leading the way is the laser beam welder, a cutting-edge solution that has transformed traditional welding methods. Known for its accuracy, efficiency, and adaptability, this tool has become a game-changer in sectors ranging from automotive to electronics. At LaserChina, innovation meets precision, making high-performance welding more accessible than ever.

What Makes a Laser Beam Welder Special?

Unlike conventional welding that relies on heat from electrical arcs, a laser beam welder harnesses the energy of concentrated light. This intense, focused beam penetrates metals with remarkable speed and precision. The result is a seamless weld that minimizes material distortion, reduces post-processing, and delivers a clean finish. Industries seeking flawless production have quickly realized the unmatched benefits of this technology.

Advantages of Using Laser Beam Welding

- Extreme Precision – The laser’s pinpoint accuracy ensures even the smallest, most delicate parts can be joined without damaging surrounding areas.

- High Speed – Faster welding cycles lead to greater productivity, cutting both time and operational costs.

- Strong, Clean Joints – Weld seams are robust, smooth, and aesthetically pleasing, eliminating the need for extensive polishing.

- Versatility – From stainless steel and aluminum to exotic alloys, a laser beam welder adapts to a wide range of materials.

- Minimal Distortion – Reduced heat input ensures parts retain their original shape, which is crucial in precision industries.

Applications Across Industries

The demand for laser beam welders continues to grow as industries discover new possibilities:

- Automotive Manufacturing: Creates strong joints for lightweight car components.

- Medical Devices: Produces fine welds on surgical tools and implants.

- Electronics: Enables precise joining of delicate circuit parts.

- Aerospace: Ensures durable, lightweight welds essential for performance and safety.

Each application highlights how this technology not only improves efficiency but also enhances product quality on a global scale.

LaserChina: Leading the Way

When it comes to advanced welding solutions, LaserChina stands as a trusted name. With years of expertise, the brand delivers machines engineered for accuracy, reliability, and long-term performance. A laser beam welder from LaserChina is designed to meet the demands of modern industries while offering flexibility to handle both small-scale projects and mass production needs.

Conclusion

The future of welding lies in innovation, and the laser beam welder is the ultimate proof of that evolution. Precision, speed, and versatility make it a powerful tool that no forward-thinking industry can ignore. LaserChina continues to drive progress, providing the perfect balance between cutting-edge technology and practical solutions for real-world applications.